HISTORY OF ORIENTAL RUGS

The origin of the Persian knotted rug is shrouded in mystery. However, we do know that the earliest pile–woven rug dates back to the 5th century B.C. It was discovered frozen in a Scythian burial site in the Altay Mountains of Siberia near the northeastern border of Mongolia. Modern carbon dating has placed it at 2,500 years old. The discovery of the Pazyryk rug proved that pile weaving is an ancient craft.

The size of the Pazyryk carpet was 6’ by 6’, and was woven with symmetric knots of about 200–225 knots per square inch. The design has a dominant tile–work central motif surrounded by borders featuring rows of elk and horsemen.

Even though it has Persian motifs, the source of the Pazyryk carpet is uncertain. Some scholars believe that it was made in Persia and was imported. Others disagree and believe it was made near the area where it was found. Currently, the Pazyryk carpet is displayed in the Hermitage Museum in St. Petersburg, Russia.

PARTS OF A RUG DESIGN

Traditional rugs are comprised of two sections: the border and the field. The border is the main decorative design that surrounds the rug. Some rugs also have guard borders– narrow decorative designs adjacent to the main border. The field is the area of the rug located within the borders. This can sometimes contain an all over pattern or a medallion, which is most

often a round, oval, or polygonal design.

These two parts are also important in identifying the rug. The dominant color in the field and border respectively end up in the name of the rug (i.e., Pietra 6265F Red/Gold). Red is the dominant color of the field and gold is the dominant color of the border.

THE DESIGN

Just as an architect needs a blueprint, the weaver must also have a plan as to how the finished rug should look. There are two popular ways of doing this: cartoon mapping and Talim cards.

With Talim cards, one person reads the color and number of knots to several weavers, who then follow the instruction of the reader. When employing this method, it is possible that the weaver might never know what the finished product will look like until it has actually been completed!

The most commonly used technique, cartoon mapping, is a full–scale graph paper chart that tells the weaver what color each knot is to be. Each tiny square represents one knot. For rugs that have symmetry in design, the plate usually illustrates one quarter of the rug. Famous artists and designers often draw the cartoons, which are mostly used in workshops and master workshops. Designs of smaller tribal rugs are usually woven from memory, often handed down from father to son and mother to daughter.

A motif or design may be asymmetrical (the boteh motif), or it may be symmetrical (the dyrnak gul motif). It is the collaboration and repetition of these two design elements that form a pattern and define the design of the rug.

the rug.

As we often see in Oriental rugs, it is the playfulness with symmetry that results in intriguing patterns. In nature as well as art, symmetry is imperfect. It seems that the approximation of symmetry, rather than its precision is what teases the mind as well as the eye.

WOOL TO YARN

There are three fibers that are predominant in traditional rug production: wool, silk and cotton. Wool and silk are chiefly used for the knots that form the pile. Usually, cotton or wool is employed to create the important warp and weft threads. In today’s fine rugs, cotton is used almost exclusively for warp and weft threads, because cotton gives the rug more strength, and a more even–looking, flatter–lying rug.

Sheep’s wool is the most important material in Oriental rugs. The very texture of wool makes surface dirt less apparent, ensuring that the rug will stay "cleaner looking" much longer than a rug made from any other fiber. In addition, wool also has a strong attraction for dye, so colors will remain true and resistant to wear. Also, wool has a natural resilience that gives it superior ability to withstand matting and crushing. Finally and most importantly, wool has the longest life of any carpet fiber. The natural elasticity of wool also makes woolen fabrics resistant to tearing.

The quality of the wool is another important factor in rug production. Luster and strength vary according to the breed of sheep, the climactic conditions in which the sheep are raised, and

the season during which shearing takes place. Equally important is the part of the sheep from which the wool is taken.

takes place. Equally important is the part of the sheep from which the wool is taken.

Wool from the shoulder and flank sections is regarded as the most desirable fleece on the sheep. Sheep from mountain regions have longer fleece. Winter fleece produces thicker and heavier wool, while spring fleece is softer and finer. Lambs aged 8 to 14 months produce some of the finest wool, called "kork."

The preparation of the wool also has much to do with the appearance of the final product. Proper shearing guarantees maximum fiber length. This is usually done on the farm by a skilled shearer. With fast electric hand clippers similar to large barber’s shears, a good shearer can remove the fleece from a sheep in about 5 minutes. The shearer usually peels the fleece off in one piece. Fine and medium–fine wools of longer staple lengths (more than three inches) usually go to make lightweight worsted suit and dress fabrics. Coarser and shorter fibers (less than three inches) usually go into bulky sweater and carpet yarns.

The next step in the process is washing, or "scouring." Scouring removes grease (unrefined lanolin), vegetable matter, and other impurities that gather in the wool from the range, feedlot, or shearing floor. A set of rakes moves the fleece through a series of scouring tubs of soap and water. Impurities can account for 30 to 70 percent of raw (unscoured) fleece’s weight. The first wash waters are warmed up to 140°F and are followed by a cold rinse. Then squeeze rollers and a hot–air drying chamber bring the moisture content to the right level for the next step in the process, which is carding.

The carding process passes the clean and dry wool through a system of wire rollers to straighten the fibers and remove any remaining vegetable matter. The rollers vary in diameter and turn at different speeds in order to form a thin web of aligned fibers. Smooth steel fingers then divide the web and roll the strands over onto one another to create narrow continuous ropes of

fibers called "slivers."

The machinery gently twists the slivers (three inches or less in length) into ropelike strands called "roving," then winds the roving into balls ready for spinning into woolen yarns. Wool that’s longer than three inches usually goes straight to the combing and drawing steps, which prepare it for spinning into worsted yarn.

Roving for both yarn lengths goes through the spinning process for yarn formation, making it suitable for weaving or knitting. After spools of roving are in place on the spinning frame, the ends of the roving are drawn through small rollers to extend the wool fibers even further. Then the spinning machines twist and retwist the roving into yarns of a wide variety of qualities defined by strength, firmness, size and ply. After the spinning process, the yarn can be dyed.

DYES

Without vibrant and radiant colors, Oriental rugs would likely be less desirable works of art. The traditional art of dyeing allows for the magnificent decorative effects seen in rugs. Family recipes for specific colors have been closely guarded and often passed down from generation to generation.

Most rugs contain either natural or synthetic dyes. Natural dyes are made from vegetable or mineral sources. Madder root, saffron, pomegranate, walnuts, indigo and iron oxide are all used in the creation of natural dyes. Synthetic dyes are made from either aniline or chrome. Aniline dyes are derived from chemical processes rather than from natural resources. Developed around 1940, chrome dyes use potassium bicarbonate and come in a wide range of rich colors.

Until the late nineteenth century, only natural dyes were used for coloring weaving yarns. Synthetic aniline dyes made from coal tar were brilliant, inexpensive, and easy to use; however, they faded rapidly with exposure to light and water. When chrome dyes came along, they were proven colorfast and non-corrosive to the wool.

Today, mostly chrome synthetic dyes are used to color weaving yarns. Natural dyes are used in places where they are easily obtainable. Sometimes the two types of dyed yarns are used side by side in the same piece.

For both dye types, vats of water are hand–fired and then the dye is added to the water. The yarn is then placed into the boiling mixture and stirred around until it reaches the desired color. Next, it is removed from the vat and hung on lines to dry in the sun. Once the yarn is dry, weaving can begin.

THE LOOM

After the wool has been colored and processed, it is ready to weave. There are two types of looms: vertical and horizontal. Vertical looms are most commonly found in weaving factories and are nothing more than a sturdy frame, usually made of wooden timbers, designed to hold taut the warp strings upon which the weaver ties rows of knots. Beginning on the ground, the weavers

work to the top. They are gradually raised on a type of scaffolding as they come closer to completing the rug.

gradually raised on a type of scaffolding as they come closer to completing the rug.

Vertical looms are more difficult to move than the horizontal looms, which are often found in people’s homes. Horizontal looms were originally used by nomads, and are easy to pack up and move, as the nomads’ lifestyle necessitated. The horizontal loom is basically the same as the vertical loom, except that the rug is woven parallel to the ground. When it is necessary to move the loom to cook, eat, or sleep, it is simply rolled up and put aside until work can begin again.

Looms hold the foundation threads, called the warp and the weft in place so that knots can be tied around them to form the pile. The warp fibers run up and down on vertical looms. The finer a rug’s quality, the thinner the warp fibers are and the closer they are together. Weft fibers simply weave in and out of the warp fibers. Weft fibers separate rows of knots in all pile rugs.

Knots are the yarns woven around the warp and the weft. Knots can be counted from the back of the carpet, and this count can often determine the quality and cost of a rug. The finest rugs have from 400 to 700 knots per square inch. On average, most rugs have from 90 to 250 knots per square inch.

As rows of knots are completed, the weaver must pack them down with a large metal comb. The loose ends of these knots form the pile of the rug, or the part on which we walk. Periodically, the weaver will sheer off some of the extra yarn that has been left on the knots. By trimming the pile, the design becomes sharper.

After the entire rug is finished and taken off the loom, it is sheared once again. At this time extra details can be added by hand carving or embossing the rug. This process involves highlighting certain features of the rug by cropping the surrounding yarns. The shearing and embossing of the rug are perhaps the most difficult tasks and thus require highly skilled workers.

WEAVING KNOTS

The different types of knots can be used to place the rug’s geographic origin as well as to determine the appearance of the pile, or lack thereof. It is important to remember that not all rugs have piles; those that do not are called flat weaves.

The Turkish, or Ghiordes knot is characteristic of the pieces woven by the Turkish and Kurdish tribes of Turkey, Iran and the Caucuses. The Turkish knot is sturdier than the Persian, or Senneh knot, but produces a less fine weave.

The Jufti knot or "false" knot can be either Persian or Turkish in style and makes the weaving process faster. Even though this technique uses half the material and only takes half as much time, it will probably last only half as long!

The Tibetan Knot is a distinctive rug–weaving technique. A rod, which establishes the length of the pile, is put in front of the warp. A continuous yarn is looped around two warps and then once around the rod. When a row of loops is finished, the weaver cuts the loops, thereby freeing the rod and creating the pile.

Knot density is the measure of knots per unit area of a rug. Knots are counted vertically and horizontally within the given area along the back of the rug. Knot density is affected by many factors: the size of warp, weft and pile threads, the presence or absence of warp depression, and how tightly the weaver packs down each row of knots. Knot density is important because it can determine the quality of the rug. The more knots per unit the rug contains, the higher the quality.

pile threads, the presence or absence of warp depression, and how tightly the weaver packs down each row of knots. Knot density is important because it can determine the quality of the rug. The more knots per unit the rug contains, the higher the quality.

Grading Knot Counts:

- Course: Up to 25 knots per square inch

- Medium: 40 to 90 knots per square inch

- Fine: 90 to 166 knots per square inch

- Very Fine: Over 167 knots per square inch

RUG QUALITIES

Oriental rugs come in many different colors, styles and shapes. There are also several different ways to make these beautiful floor coverings. Some constructions are preferred over others, but the end product should still be something suitable to adorn your home.

Oriental rugs can be divided into two categories: handmade and machine made. Handmade rugs can be sectioned further into three types: hand knotted, hand tufted and flat woven. Machine made rugs are also called "power loomed" rugs.

Hand knotted rugs are by far higher in quality than machine made rugs. These investments, possessing a high resale value, will last through generations. The construction of these rugs is much stronger than hand tufted, flat woven or machine made rugs. The fringe in a handmade rug is actually the warp thread of the rug, running through the rug from end to end. The knots tied are compacted tightly to form a very dense and strong structure that can withstand many years of hard use.

The piles of hand tufted and hand hooked rugs are constructed by injecting a "U" shaped loop of yarn loaded onto a tufting gun through the back of a canvas backing to form the pile. Tufted and hooked rugs differ because tufted rugs are sheared or cut to look more like carpet, whereas hooked rugs are left unshorn with the "U," or hook shape, to form the pile. The height of the pile is determined during the making of the rug. There are 3 qualities of hand hooked rugs based on the density and size of the loop. Gross Point rugs, known in the industry simply as "hooked" rugs, have large loops (1/2 inch high) forming the pile. Petit Point rugs have piles made of smaller loops (1/4 inch high), and a Micro Point rug’s pile has very tiny loops (1/8 inch high). As loop size decreases, the amount of detail in a rug’s design increases, thus one can achieve a much more intricate design by using the micro point hook than by using a petit point hook or gross point hook.

Hand tufted and hand hooked rugs are affordable alternatives to authentic hand knotted rugs. The pile side of hand tufted rugs often looks and feels just like that of an authentic hand knotted rug. The fast tufting technique enables the manufacturer to produce these rugs more quickly and with less labor, enabling faster delivery to the market. It is for these reasons that hand tufted rugs can easily cost 10 times less than a hand knotted Oriental rug of the exact same size.

Flat woven rugs are pileless rugs. Some common flat weaves are Kelims, Dhurries, Soumaks, Needlepoints, and Aubussons. Aubussons are woven on looms. The cartoon is placed directly behind the loom so the weaver can look through the warp strings at the diagram. Unlike pile rugs, the weft in Aubusson rugs is actually what forms the designs in the rug. Aubussons are made using a slit tapestry weave, which means that the colors in the rug are physically separate from each other and must be sewn together once the rug has been removed from the loom.

Once the design for a Needlepoint rug is complete, it is placed underneath the canvas that will serve as the rug’s foundation. Workers peer through the canvas to follow the design, which is spread out flat underneath. Using a stitch similar to a cross–stitch, workers stitch directly onto the canvas. Flat weaves are backed around their borders with a durable fabric to ensure that the finished products will lay flat and have a prolonged life.

Machine made rugs are woven on power looms operated either by hand, machine or computer, hence their alternate name–"power loomed." The design and colors are determined, and a computer card is created which tells the computer which size and color rug it needs to produce. The loom is strung with a warp of jute, or sometimes cotton. The rug is then woven using wool, nylon, polypropylene, olefin or another suitable yarn. Some common synthetic materials are olefin, which is resilient and if heat set, is not as shiny as many others; polypropylene, which tends to flatten more readily; and nylon which is generally less durable. There are two types of looms used to create three different categories of Oriental reproductions: Wilton, Cross–woven Wilton, and Axminster. Each of these can be designed to achieve various pile heights, densities, finishes and qualities.

Even though some machine made rugs are poor imitations of their handmade counterparts, many machine made rugs produced today rival the look and feel of new handmade pieces. One drawback to power loomed rugs is that once they get damaged, there is very little that can be done to repair them. Handmade rugs on the other hand can be professionally repaired and remain in use for many years. But overall, power loomed rugs are an excellent value and can be a wonderful addition to your décor.

THE DIFFERENCE

Buying a rug can be tricky! Don’t know what you’re buying? Check these 3 places:

ENDS: In a hand knotted rug, the fringe is "part" of the rug — NOT sewn on as an extension, as is the case in hand tufted and power loomed rugs.

BACK: Hand tufted rugs are almost always covered with a cotton/canvas backing. The pattern is clearly visible on the backside of hand knotted rugs.

SIDE: Hand tufted rugs always have "serged" sides or machine stitching on both sides of the rug.

CHEMICAL WASHING

After a hand made rug has been removed from the loom and trimmed for a final time, it must be washed. The rug first undergoes a chemical wash whereby chemicals are poured onto the rug and paddles slightly larger than rowing oars are used to beat the rug. The rug is then rinsed with water to give it a final cleaning. The chemical wash softens the yarn and gives the rug a silky feel.

Next, the rug is drenched in water and beaten with the paddles again. This process is repeated for approximately four to eight hours. The rug is then set out in the sun to dry. If an antique finish, or patina, is desired, an acid wash must be applied to the rug prior to the chemical wash. The acid wash will fade colors in certain spots to give new rugs an antique look.

RUG CARE

Oriental rugs have a well–earned reputation for being extremely durable and can be expected to provide years of service. However, they are not indestructible and should be well–cared–for, like all prized possessions. Once you become the proud owner of an Oriental rug, it is important that you know about the characteristics and care of your rug. Proper care and maintenance will greatly enhance both the beauty and the life of the rug. The construction of your rug, the fibers with which it has been made and the environment in which it is placed will all play in to the rug’s longevity. In addition to normal wear and tear, central heating, air conditioning and a number of household chemicals and inhabitants can have a damaging effect on the construction of your rug. Do not place the rug in damp areas as dampness may cause deterioration of your rug and never place the rug near any heat or fire ignition sources.

Correct Underlayment

It is extremely important, no matter how smooth your floor may appear to be, to always place a suitable padding between the floor and your rug. Ideally, a pad should:

- Keep the rug from slipping

- Absorb the pounding that all rugs receive underfoot

- Allow for air circulation, which will prolong the life of your rug

- Be cut one inch smaller in length and width than the rug itself

There are a number of underlays on the market today. The two most widely used are those made from porous sponge rubber and those made from a combination of fibers with a self–adhering coating that looks like a compressed sheet of cotton. The rubber underlay is used on hard surfaces like hardwood, tile, stone or concrete. The self–adhering underlay is mostly used when placing an Oriental rug on wall–to&ndwall carpeting.

Zin Home does not recommend placing rugs on wall–to–wall carpeting, as rugs of all construction have a tendency to float or crawl, stretch and wrinkle in these situations, especially when heavy furniture is being placed on them. If you do wish to place a rug on top of wall–to–wall carpeting, it is best to lay it on carpeting that has a short pile. The low–pile commercial broadloom carpeting that banks and department stores use is ideal.

Note of caution: Do not use sheets of plain foam rubber on a polished floor. They tend to collect moisture that will cause stickiness. The dampness will also cause deterioration of your rug.

Cleaning Your Rug

Like everything else, rugs get dirty, and since self–cleaning itself can involve wear–and–tear, cleaning should be undertaken carefully. Sweeping your rug with a broom or carpet sweeper on a weekly basis is highly recommended and is the least damaging way to routinely clean your rug. Depending on the size, beating your rug "the old-fashioned way" is also an excellent cleaning method that causes little wear to your rug. Vacuuming your rug once every other week is a fast and efficient way to remove the grit that might cut into rug fibers. For routine cleaning, you should be sure to use a machine that works only on suction and does not use a beater bar. When vacuuming, it is advisable to do so with the nap. Vacuuming against the nap can press dirt back into the rug’s pile. Vacuuming a shag rug with a long pile is never recommended.

Once a year, you can clean your rug with a vacuum that has beater bars. First, vacuum the back of the rug. The beating effect should cause any trapped grit to fall out of the pile. Then, turn the rug over and vacuum lightly across the face. Make sure that the beater bar is in a high enough position so it is not slowing the vacuum’s motor excessively when pushing it over the rug’s pile. Vacuums with extremely violent beater bars should be avoided because they may damage the rug’s foundation. In all events, care should be taken never to vacuum the fringe of a rug, especially with hand knotted pieces. In hand knotted rugs, the fringes are truly pieces of the rug’s foundation. If damaged, the entire rug may be at risk of unraveling. It is also essential to replace worn rug pads as necessary. Your annual beater bar vacuuming is a good time to check the state of your rug pad. In order to ensure that your rug wears evenly, you may also want to rotate it 180° at this time as well.

If the rug was clean when you bought it and is not in an unusually high–traffic area, you should only have to cope with major cleaning once every three to five years. Only a qualified and reputable cleaning company with good references and insurance should undertake the cleaning of an Oriental rug, as techniques are different from those used to clean wall–to–wall carpeting. Professional rug cleaning involves huge machines that feed the carpet over giant rollers and wash the rug with high–pressure jets of water tinctured with a gentle detergent. The rug is then rinsed and wrung between huge cylinders and hung on a bar located in a chamber with circulating hot air for drying. While this process is perfectly fine for newer rugs in sound structural shape, older rugs should be hand washed horizontally with utmost care. Zin Home always recommends professional cleaning services as the safest and surest way to protect the life of your rug, regardless of rug construction and fiber content.

Accidents always happen, whether someone spills a plate of spaghetti or a glass of red wine or coffee. Always have a bottle of plain soda water available. The bubbles in soda water dilute and lift the stain and work well on most stains if applied immediately. Lightly dampen a white cloth with soda water and gently massage the stained area from the outer edges in, rubbing in a circular motion. Make sure that your cleaning cloth is only lightly dampened. Excessive moisture can damage your rug. Stains that have been allowed to dry can often be much more difficult to deal with, however dried mud and blood can often be simply brushed away. For rugs laid atop carpeting, do not conduct any cleaning and/or maintenance prior to removing the rug from the carpet and do not return the rug until completely dry, as applying moisture to the rug while still on the wall–to–wall carpet could cause the colors in both the rug and carpeting to react to each other.

Uric acid is acid in urine that bleaches colors and destroys wool and other fibers. When your pet or baby has an accident, wash the stain three or more times with plain soda water as directed above, blotting the stained area with a white towel each time. Then, apply a cleaning solution made from baby shampoo (or any shampoo that doesn’t contain bleach) and white vinegar at a ratio of one teaspoon of vinegar per pint of shampoo. Test the rug first in a small area to ensure color–fastness. Rinse well with clean water, brushing the pile with a medium brush and air–drying thoroughly with cool air. For large areas needing cleaning, professional services are recommended.

Hand Knotted Rugs

Generally speaking, hand knotted rugs are the most durable rugs with regard to construction. It is important to realize that within the hand knotted construction, qualities can range from very high to very low, not only in knot count, but also when describing the wool or other materials used in the weaving of the rug. Depending on the overall quality of the rug and the care you give it, these pieces can last for generations. Make sure you never vacuum the fringes of a hand knotted rug. Hand knotted rugs can be stored either rolled or folded, depending on the knot density. For higher knot count rugs, rolling is preferable to prevent breakage of the foundation. Should the fringe of your hand knotted rug become damaged, it is best to seek help from a reputable rug repair workshop.

Hand Tufted Rugs

While hand made in quality, these rugs are not knotted by hand and are made with the assistance of a tufting gun. Hand tufted rugs are often less expensive than hand knotted pieces and can often be more fashion–oriented. Because these rugs take less time to produce, hand tufted pieces can follow the latest fads and color trends. Whereas a hand knotted rug might take months or years to produce, hand tufted rugs usually take only a matter of days or weeks. As with hand knotted rugs, there are a wide range of qualities offered within the tufted category. These are mainly differentiated by pile fiber types and qualities and the density of the tufts.

Because the rug is tufted, there are no knots to anchor the yarns of the pile in place, thus a canvas backing glued to the back of the rug with latex keeps them secured. Over time, the rug’s backing may become stiff, the latex may deteriorate into a non–toxic white powder or it may begin to emit a smell similar to burnt rubber. This is a characteristic of the latex and is not considered to be a defect. Please be aware that any type of spill or accident that exposes your tufted rug to moisture may accelerate this process, especially if care is not taken to clean and dry the rug immediately. Many people do not find the repair of a hand tufted rug to be cost effective due to the fact that they are relatively inexpensive when compared to hand knotted rugs. Repairs to hand tufted rugs are possible, but should be undertaken only by reputable rug repair specialists.

When storing a hand tufted rug, it is important that it never be folded, but rather rolled in a tight cylinder shape to prevent the foundation from breaking or the backing from wrinkling. Never place heavy objects on top of a rolled rug, as it will create creases in the rug and can even break the backing. Should the fringe of a hand tufted rug become detached, it can often be simply sewn back on to the rug.

Power Loomed Rugs

Power loomed rugs, alternately known as machine made rugs, are woven on machines often controlled by computers. There are varying qualities of power loomed rugs. Density, fiber content and number of colors used are all considered in determining the rug’s quality. Because power loomed rugs can be produced in a matter of minutes, these pieces are often much more fashion–oriented toward the trends of the day. The investment of resources and time in the creation of a power loomed rug is generally much less than in that of a hand knotted or even a hand tufted rug, and the cost is a reflection of that.

One drawback to power loomed rugs is that once they get damaged, there is very little that can be done to repair them, and it is usually not cost–effective to do so. Some power loomed rugs have fringes and others do not. Those that have fringes are fringes that have been sewn on, and care should be taken to avoid vacuuming them as they can easily come apart from the rug. Should this occur, they can be sewn back on, provided no damage has been done to the rug’s foundation. Additionally, it should be noted that the serging at the edges of a power loomed rug can unravel when cleaned or vacuumed incorrectly (see "Cleaning Your Rug").

It is preferable that Power loomed rugs are stored rolled rather than folded, as the rug’s foundation could be adversely affected by folding, and creases may appear if the rug is folded. Just as with a tufted rug, you should not place objects on top of a rolled power loomed rug as creasing is likely to occur.

Characteristics of All Rugs

Your rug may exhibit some or all of the following characteristics:

Shedding: It is characteristic for all synthetic and wool pile rugs to lose short fibers. This "shedding" process is often created when the pile is cut to required height during production and fibers fall onto the surface as "fluff." Shedding is not considered a defect. The amount of shedding will vary based on material type and quality, pile height, age of the rug and knot density.

Sprouting: Certain types of yarns used in the making of rugs are "over-twisted" in order to give the rug the desired texture, and often a yarn tuft will rise above the surface (commonly called "sprouting"). Sprouting is one of the easiest issues to remedy by merely cutting the sprout (the yarn sticking up above the surface) with a pair of scissors so that it is flush with the rug’s surface. DO NOT PULL THE SPROUT AS IT CAN CAUSE ADDITIONAL DAMAGE TO THE RUG. Also, be aware that high heels can cause sprouting as well, even in flat–weave rugs.

Curling: The term "curling" can be used to describe a couple of situations with respect to your rug. Rugs are often shipped rolled tightly into a cylindrical shape. Sometimes, when the rugs are initially unpacked, the edges will curl under, refusing to lay flat. The rug’s foundation or backing must be given time to relax after being unpacked. Often times, reverse rolling the rug will speed the relaxing process. Curling can also be a sign in hand knotted rugs of a very finely and tightly woven piece. Often times, sewing strips of leather along the edges in cases such as these will prevent curling. This should be undertaken only by a professional rug repair workshop.

The term "curling" is also used to describe the stretching/wrinkling that occurs when a rug is placed on top of wall–to–wall carpet, often times with heavy furniture placed on the rug’s surface. Again, this is not a defect of the rug, although in such cases the rug will never lay flat again. It is simply due to the fact that the rug’s foundation has been stretched.

Other Maintenance Facts

Insect Damage: Rugs should be checked periodically for evidence of insect infestation, which can be brought into your house by pets, flowers or food. Your rug’s worst enemy is the moth. While adult moths will not eat wool, their larvae feed on it in dark, quiet, warm places, such as areas hidden under furniture. Therefore, regular cleaning is necessary to avoid moth infestation. Moving your rug into the hot sun for a few hours every now and then is a good precaution. Moths are most active during the summer months, so exercise special care during this time. While there are anti–moth sprays on the market, you must be sure that they will not harm your rug’s fibers or colors before applying them.

Camphor powder has been used for many years to deter moths. Dusting the back of your rug with camphor powder and lightly shaking it can be an effective preventative measure.

Crushing: Heavy furniture may damage your rug. If the feet of your furniture are sharp or are made of metal, you must use some sort of protector prior to setting such furniture on top of your rug. There are many types of protectors available. Furniture floaters, which have a smooth surface and adhere directly to the legs of your furniture, leave minimal indentations on the surface of your rug. If the pile of your rug has become crushed and you wish to attempt to restore it to its normal height, try brushing the affected area gently with a soft brush.

Fading: Excessive fading can occur if a rug is exposed to long periods of strong sunlight and is best avoided by either repositioning the rug or drawing blinds or draperies. Any light over the years, however, will gradually mellow the colors and sometimes this subdued coloration can be an advantage. Faded, mellow colors are often very appealing to many rug connoisseurs.

Cleaning Products: While you will certainly want to ensure that all cleaning products you may choose to apply directly to your rug are safe and will not cause damage to your rug, you should also be aware that some cleaning agents used in close proximity to your rug can have harmful effects, although they might not be applied directly to the rug itself. Perform a thorough check of all cleaning agents to be used on underlying surfaces and in surrounding areas, such as baseboards, windows, etc., to ensure that they are safe to be used around your rug.

Plant Lovers, Beware: Continuous dampness resulting from over–watering and spilling of flower pots and planters placed directly on a rug can lead to mildew rot, which is an irreparable type of damage, and color transfer, if the rug is placed atop wall–to–wall carpeting.

Rug Storage: If you need to store your rug for any lengthy amount of time, first make sure that it is clean and dry. It is advisable to treat it with a moth repellent (see "Insect Damage"), then roll the rug into a tight cylinder against the nap and wrap in a breathable fabric, such as a sheet. Plastic wrapping will prevent the rug from breathing. The rug should be stored in a cool, dry, well–ventilated area. Some larger hand knotted rugs can be stored folded if not too tightly woven, however these too should be treated for moths and stored in breathable fabric. Never store heavy objects on your rolled or folded rugs, as this could cause permanent damage by creasing the rug and, in some cases, breaking the foundation or backing of a tufted rug.

STAIN REMOVAL

Every day accidents happen, but it doesn’t mean that your rug’s appearance has to suffer. Here are 6 easy steps to ensure your rug doesn’t pay the price of mishaps.

- Act Fast

- BLOT — NEVER RUB

- Clean stain – Edge to Center

- Do Not SOAK

- Pat and Fan Dry

- Brush Pile

You have to move fast when spills happen, which means you should keep a little box containing the following close at hand at all times: dry cleaning fluid, club soda, cotton cloths, white vinegar, mild dishwashing detergent (containing no alkalis or bleaches), alcohol, 3% hydrogen peroxide, clothes brush, household ammonia, salt and nail polish remover (acetone).

Scoop or scrape off solid stains with a spoon or blunt knife. Blot up excess spills with paper towels. Don’t rub, as this will spread the stain. You want the opposite of the ripple effect, working the stain from the edge to the center.

This will hopefully contain the stain and not affect the rest of the rug. Always apply antidote with a clean cloth. Do not soak the stain with cleaning solution. The less moisture the better. Then pat excess moisture with paper towels and dry with a fan or hand blow dryer, preferably on a low heat setting. Finally, to restore the pile, brush it with a soft brush. On old and stubborn stains, repeat the process until the stain is completely removed.

Special Stains:

Chewing Gum – Press ice cubes against spot until it becomes brittle and breaks off. Use spot remover to vanish last traces. Saturate the spot with a cloth soaked in vinegar or alcohol.

Candle Wax – Place a brown paper bag over the spot. Place a hot iron over the paper bag. Move iron constantly. Wait a few minutes until the wax is absorbed. Repeat if necessary.

Ink from ballpoint pen – Saturate the spot with hairspray. Allow to dry. Blot lightly with vinegar solution.

Make sure to blot after every step!

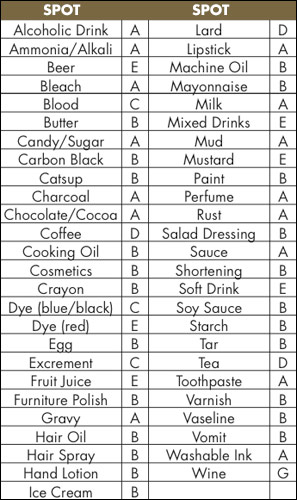

Key to Cleaning Methods

Method A: Detergent–Vinegar–Detergent–Water

Method B: Cleaning Fluids–Detergent–Water–Ammonia–Detergent–Water

Method C: Detergent–Vinegar–Ammonia–Detergent–Water

Method D: Detergent–Ammonia–Detergent–Water

Method E: Detergent–Water

Method F: Detergent–Ammonia–Vinegar–Detergent

Method G: Salt–Water–Detergent–Water

Detergent Solution: 1 tsp dishwashing liquid + 1 cup water

Ammonia Solution: 1 oz ammonia + 1 cup water

Vinegar Solution: 1 part vinegar + 2 parts water

PICKING THE BEST RUG

There are three things to consider when looking for the perfect rug: color, style, size… and (off the record), TIME!

Color is Key

Select the rug color from your upholstery, draperies, wallpaper or other dominant color in the room.

For a more dramatic and "professionally decorated" look, match the rug with an accent color from your décor. Once the rug is placed in the room, it will beautifully contrast with the overall design. To ensure color matches, keep a pillow or fabric swatch on hand during your rug search. Colors will appear different under varied lighting and the samples will aid the eye for the perfect match.

Style is Important

With thousands of rug designs and styles today, choosing a rug can be quite trying. Decide first if you would rather have a traditional or a contemporary rug. This important factor will help to narrow your search and define your possibilities in rug designs.

The Right Size

Rugs add impact by enhancing the décor that lies above it. Determining where the rug will be placed will be a direct correlation to the size of the rug you purchase. For example, in a 4’x6’ entry foyer, a rug sized approximately 3’x5’ would look most appropriate. Any smaller and the rug makes no visual impact, any larger and you lose the pleasing "framing" effect a rug creates on the flooring below.

Follow these basic rules for your size selection:

8’x11’ or larger: Dining room, large living room and large family room.

5’x8’/6’x9’: Family room, living room, small dinette, entry foyer, den and office.

3’x5’/4’x6’: Entry foyer, small family room, small living room, kitchen, bath, office area or as an accent in front of chairs and under accent tables.

Runner: Hallways, stairs or as an accent.